-

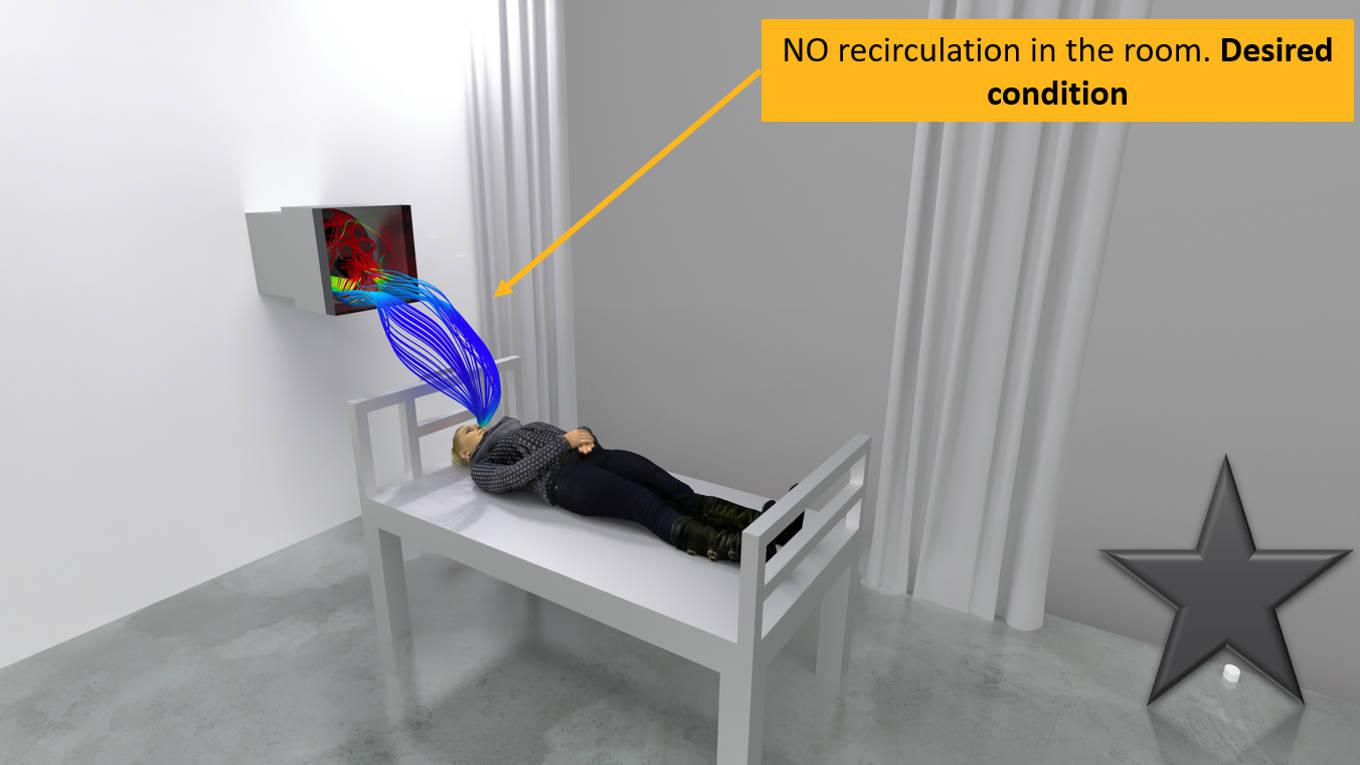

A depiction of air flow in the Negative Pressure Room. Photo courtesy: IIT Ropar

The healthcare industry was able to develop safe and reliable, low-cost ventilators as well as negative pressure rooms (NPR) and sample collection booths thanks to the science of simulation engineering, much of it by the India arm of engineering simulation software developer Ansys. With hospitals facing a shortage of ventilators amid the current Covid-19 global pandemic, Ansys India tied up with IIT Kanpur and a Pune-based start-up, Nocca Robotics, through its CSR initiative to make ventilators. Nocca, incubated by IIT-K, is developing indigenised rapidly scalable, low-cost invasive ventilators with the objective of promoting healthcare, including preventive health care. "The fact that they are indigenous also supports the nation’s Atmanirbhar initiative,” says Rafiq Somani, the US-headquartered company’s area vice president - India and South Asia Pacific. “Even in the post COVID19 phase, there is bound to be a growth in the utilisation of simulation in the healthcare industry with customised simulation products and solutions.” Explaining that Ansys has always believed in partnership between academia, government and industry, Somani says it has also been working with the IITs of Ropar, Bombay and Kanpur to develop equipment to help those affected by the pandemic.

-

A joint assessment with IIT Ropar has validated a modular low-cost NPR, used to prevent airborne transmission of respiratory diseases in hospitals

A joint assessment with IIT Ropar has validated a modular low-cost NPR, used to prevent airborne transmission of respiratory diseases in hospitals with a mechanical ventilation system that creates a lower operating pressure so that there is no ‘significant’ leakage of the contaminated air. These chambers, meant for isolating COVID-19 patients in hospitals and medical centres, ensure that released airborne contaminants do not stay suspended - or leak – outside, but are scavenged through the ventilation system. The NPR comprises of a sealed plastic canopy, a removable door around the patient’s bed and the suction-type ventilation system appropriately placed to maintain the negative pressure and efficient removal of the airborne contaminants.

The company has also evaluated, implemented and commissioned these NPRs and provided technological support to the institution to install negative pressure cabins in the government medical centres in the Rupnagar district of Punjab.

Working with professors from IIT Bombay, IIT Ropar and the Ashoka University, Ansys India came up with the design guidelines for a mobile sample collection booth conforming to BSL-2 (Biosafety Level 2) standards. These guidelines help in the design and assembly of the booths, making them easily deployed wherever they are needed.

Ansys will continue to play a major role in the functioning of many engineering companies, which are likely to increase their dependence on simulation to continue working remotely, Somani says. “This trend has caused a growing dependence on simulation versus physical testing. Engineering simulation has been able to show its worth during this COVID-19 phase,” he adds.

Biogas

BioEnergy will showcase its innovative biogas technology in India

Mobility

Ather aims to produce 20,000 units every month, soon

Green Hydrogen

German Development Agency, GIZ is working on a roadmap for a green hydrogen cluster in Kochi

Renewable Energy

AGEL set to play a big role in India’s carbon neutrality target