India’s waste generation and management problems are widely known. Indians generate 1.5 lakh metric tonnes (MT) of solid waste every day, much of it still incorrectly treated or untreated. The unmanaged waste releases toxins into the air creating air pollution, leaches chemicals into the soil and creates severe health and sanitation hazards for those who pick the waste - the unorganised ragpicker groups - and those who live near these waste collection units.

GD Environmental, co-founded by Ajit Gadgil and Abhijit Datar in December 2014, has been a front-runner in providing closed loop waste management solutions for governments and residential units in the Greater Pune region. The company’s patented technology gasification plant is able to completely manage the entire waste processing system, while building incentives for all stakeholders, creating value addition in the form of byproducts and ensuring that the highest standards of environmental safety are met. The company is a certified recycler of plastic waste.

As a result of its work, GDEPL has saved 536 tonnes of oil, 1,195 hours of electricity in MW, 4,008 tonnes of water and five acres of land (company Environmental Footprint Calculator through September 2020). Keeping in mind the various stakeholders in the system and potential partners, GD Environmental has created different business models to work with Gram Panchayats, residential townships and municipalities.

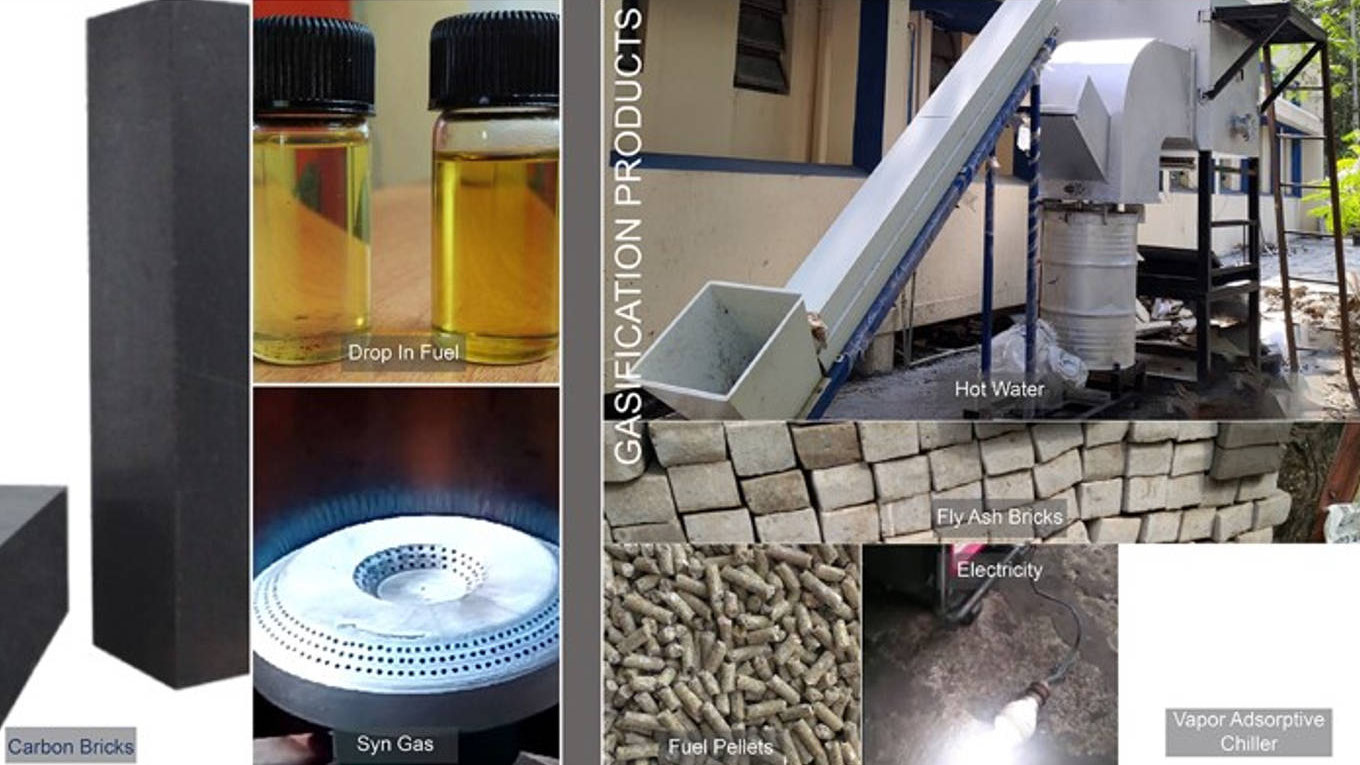

GD Environmental’s model takes into account all the stakeholders in the collection, management and processing business. The waste collectors are incentivised by segregating and removing all re-usable and salable products; the remaining landfill mass is then processed by the gasification plant, generating heat energy, which is then used to dry out wet waste and convert it into fuel pellets. An additional, and unique value-added product of the process is the creation of drop-in fuel, a substitute for high speed diesel. All other pyrolysis units currently only generate pyrolysis oil as a by-product. GD Environmental has been testing this drop-in fuel in a test vehicle for two years now, with extremely positive results.

Gasification unit does not require a chimney except for heat dissipation as sox levels are close to zero due to the unique design and process and, unlike incineration units currently used, can be located in the centre of the city, surrounded by residential and commercial spaces, with no risk of contamination or toxic pollutants.

-

GD Environmental products and their uses