-

India’s per capita electricity consumption was 1,255 kWh in 2021-22, which is one-third of the world average and one-fifth of China’s average. “Development in India is flourishing and energy demand is going to increase. But how to meet the growing demand through renewables is the challenge till they are available on a large enough scale to replace fossil fuels,” Agrawal says. “I foresee that in the next decade or two the demand for coal will continue, though it may be less than today. The energy-source mix will be different in the future, with renewable sources making inroads.”

“CIL has been growing due to the strong energy demand in the country and the delay in setting up renewable power sources. India’s per capita electricity consumption is set for a high-octane growth trajectory in the upcoming year, boosted by the central government’s schemes to prop up last-mile connectivity and the states’ intent to ensure 24x7 reliable power,” says Rupesh Sankhe, vice president, Elara Capital.

The demand-supply mismatch between thermal and renewable will help CIL in the next 3-4 years with 5-6 per cent growth though this will slide to a low single digit. However, the gap between thermal and renewable energy is narrowing, Sankhe adds. India currently has 237 GW of thermal and 114 GW of renewable installed capacity. The government has set a target to achieve 500 GW of renewable energy by 2030.

“With climate change concerns present, investor sentiment towards CIL stock has changed, as there are no long-time prospects. We suggest buying the shares at the Rs200 level,” advises Sankhe.

Opinions about coal are split and there are proponents and opponents on both sides. Both may be said to have logic on their side. However, realism dictates that a humongous energy contributor like CIL cannot abruptly disappear from the energy system. There is a great peril in that. As the world moves towards clean energy, it is evident that usage of fossil fuels will stop one day. But the big question is – when?

Pankaj Singhania, founder of Lakewater Advisors, an equity research firm in Kolkata, advises that investors in Coal India should not look at production growth in CIL but focus on growth in renewable energy asset creation instead. He says: “The profits of fossil fuel companies have huge associated indirect costs in terms of environmental decline which is not reflected in their financial statements. But how long do we think such costs can be kept away from financial statements? So, the transition to 100 per cent renewable energy has become an urgent global planetary crisis, and it is soon going to be a reality.”

“India must accelerate the development of technologies like carbon capture utilisation and storage which is still at a nascent stage in the country. These technologies have the potential to reduce CO2 emissions from energy-intensive industries,” says Agrawal.

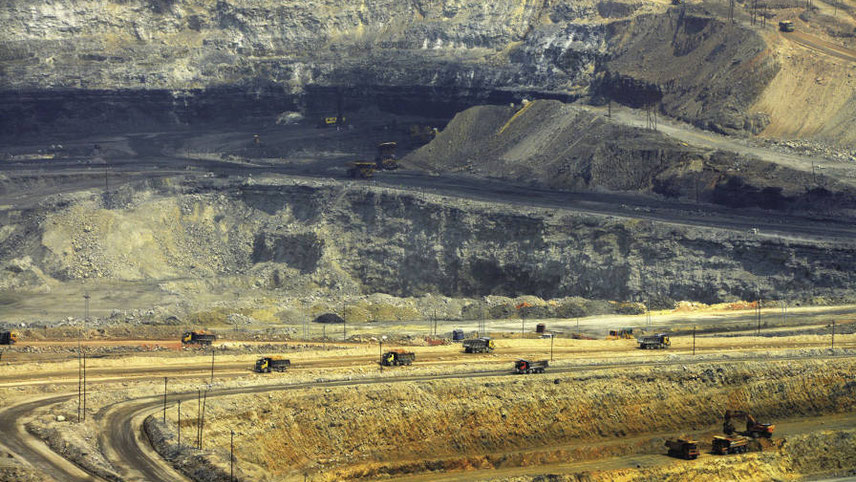

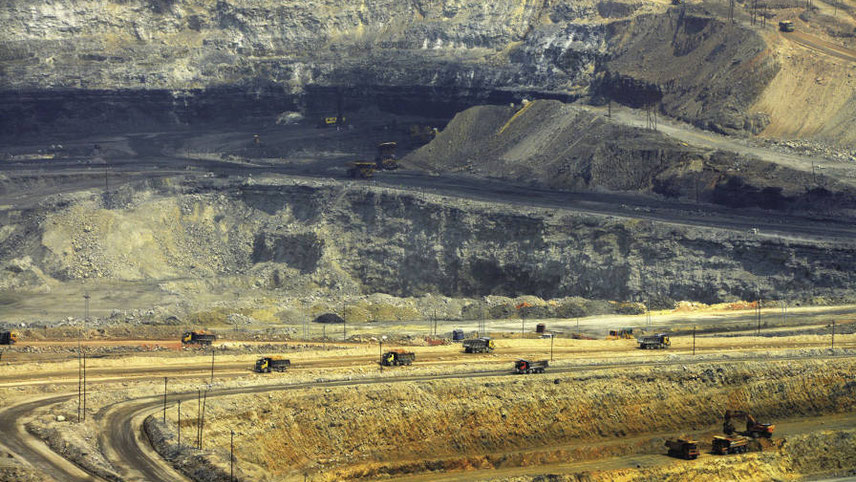

CIL’s seven coal producing subsidiaries are: Eastern Coalfields Ltd (ECL), Bharat Coking Coal Ltd (BCCL), Central Coalfields Ltd (CCL), Northern Coalfields Ltd (NCL), Western Coalfields Ltd (WCL), Southern Coalfields Ltd (SECL) and Mahanadi Coalfields Ltd (MCL). Each has raced ahead of its production targets for FY23. CIL owns 322 mines out of which 171 are opencast, 138 underground and 13 mixed coal mines.

-

Reddy: underground mining is a compulsion today for energy security

Odisha-based MCL is the largest coal producer among CIL’s subsidiaries. In FY23 it produced 193.2 MT which constitute 27.5 per cent of CIL’s total production. MCL benefits from a lower cost of production – Rs800 per tonne as against the average cost of Rs1,100 – due to the reduced burden on the coal seam in its mines. SECL made a significant turnaround and produced 167 MTS in FY23, which is 24.5 MTs higher compared to last year’s 142.5 MTS. Similarly, Rajmahal OC, the flagship producer of ECL, ramped up its production pace this month, overcoming the land issues that had plagued it during the year.

As prices have not risen for 5 years despite the increase of input costs for coal production, subsidiaries like BCCL, CCL and WCL were experiencing high production costs. Unless all stakeholders – including the government – come on board, it is difficult to raise the price of coal. But Coal India was actively working on a mechanism to help these subsidiaries raise their coal prices.

And after a long wait, the public sector miner is expected to announce the revision of non-coking coal prices by 8 per cent. But the hike will be only for the high grade – grade 2 to grade 10 used in cement, sponge iron and fertiliser industry. This will help BCCL, ECL and WCL. In fiscal 2022–23, the total volumes from coal grade 2 to coal grade 10 (G2–G10) stood at 20 per cent.

Reacting to the question of whether subsidiaries can become independent, Agrawal explains: “Some subsidiaries are very efficient as they have a low cost of production, while some lack this cost efficiency and make losses. So, they have to close down. Today we have a uniform policy for all subsidiaries and they operate in an organised manner. The synergy of being a large company is great. I do not see any advantage in spinning off subsidiaries and create unnecessary competition among them.”

CIL’s Over Burden Removal (OBR) rose to a new record of 1,656.9 cubic metres this fiscal, representing a 21.6 per cent increase compared to last year and 101.4 per cent of the target. The previous high of OBR was 1,362 cubic metres in FY22.

Growth in OBR is an encouraging indicator and bodes well for CIL in ramping up production in the first quarter of FY24, especially when faced with a challenging target of 780 MTS. OBR is the rock or soil layer that needs to be removed in order to access the coal seam for extraction in mines.

A game-changer

Both energy and environment need to be secured. CIL has taken several initiatives to safeguard the environment under the leadership of Agrawal who will retire at the end of June. PM Prasad, the present CMD of Central Coalfields Limited (CCL) will step in his shoes as the new CIL Chairman in July. Agrawal is known as gamechanger among his colleagues and taken CIL to a new level. But two years tenure for a chairman is too short for a behemoth like CIL to achieve its diverse targets.

The national miner initiated eco-friendly mechanised coal transportation under First Mile Connectivity (FMC) three years ago. FMC entails moving coal through piped conveyor belts from pitheads to loading points. From there the coal is loaded into rakes through a computerised rapid loading system with a combination of coal handling plants and silos. This reduces the load on the road and any resultant dust pollution. It also helps in the loading of a precise quantity of quality coal with minimal human intervention.

-

Choudhary: maintaining adequate coal stocks to meet summer demand

“When coal is transported from one point to another it causes a high level of pollution. This can be controlled through mechanised coal evacuation systems which will eventually replace road transport. The carbon footprint will be greatly reduced when FMC projects are implemented at full capacity,” says Agrawal. Railway infrastructure is also being built at the mines for this smooth evacuation system.

Mechanised loading is implemented in three phases comprising 59 projects with the aim of transporting 763.5 MTs of coal. The first phase involves 33 projects of 382.5 MTPA capacity, the second phase has 9 projects of 57 MTPA capacity while the third phase 17 projects of 324 MTPA capacity. Post the commissioning of all the three phases by 2029-30, CIL will have a rapid loading capacity of 914.5 MTPA. This includes the 151 MTPA capacity already operational prior to the initiation of the three phases.

“The FMC ensures faster and more accurate loading quantities on to the railway wagons compared to loading with pay loaders. So, there will no overloading demurrage, typically Rs15 per tonne charged by the railways. Through FMC, we will be saving approximately R400 crore a year and reducing the loading turnaround time,” says B. Veera Reddy, director, technical .

Though a late starter, CIL has also ventured into clean energy. “Solar power generation sits high in our priority list of renewable energy. We have lined up solar power projects of 3,000 MW capacity by FY26 through joint venture models,” says Agrawal. Giving a boost to its solar power initiative CIL signed an MoU for setting up a 1,190 MW solar power project with the Rajasthan government at an estimated cost of Rs8,000 crore.

Ground-mounted solar projects of 200 MW capacities have been awarded to various subsidiaries while a 100 MW project has been awarded in Gujarat. These projects are at different stages of installation and there are plans to add further capacity by using vacant or mined-out land parcels. Approximately 11 MW of rooftop solar projects have been commissioned and are generating cleaner energy. 20 MW additional rooftop projects have been identified and are being finalised. Currently, CIL has solar installed capacities of 300 MW.

In a two-year period CIL’s plantations in its mining areas have almost doubled, reaching the current 1,613 hectares from 862 hectares in FY21. CIL has been converting its abandoned mines into eco-parks which have become popular as eco-tourism points. A total of 30 such eco-parks are already attracting steady footfalls. Plans are afoot for the creation of more eco parks, eco-tourism sites and eco-restoration sites in mining areas.

NCL is a Singrauli-based subsidiary in Madhya Pradesh which operates through its 10 highly mechanised opencast mines which produce 131.2 MT of non-coking coal between grades G5 and G13, besides de-shale coal and coal rejects. More than 87 per cent of the coal produced is dispatched to the power sector. It contributes to about 16 per cent of the nation’s coal production. “We maintain stringent quality control of our coal. We also enjoy a locational advantage being in central India and the customer’s preferred choice,” says NCL chairman-cum-managing director, Bhola Singh.

Infrastructure modernisation

Major steps have been taken by NCL to modernise its infrastructure. NCL has high-capacity equipment such as electric rope shovels (eg 20 CuM) and electric dumpers (eg 120-tonne, 170-tonne, 190-tonne, and 205-tonne). It has the world’s best over-burden removal system, including 23 draglines. NCL is also home to Coal India’s biggest dragline, Somnath (33/72) which has a bucket size of 33 CuM.

NCL has also deployed eight surface miners for coal production. Surface Miner Mining is a blast-free, eco-friendly mining method and does not require conventional drilling and blasting operations. It has also developed eco-friendly transport infrastructure, including the FMC system, Coal Handling Plant and a belt pipe conveyer system for eco-friendly evacuation.

-

Nanda: exploring several diversification initiatives

These subsidiary mines have a huge OBR capacity. In FY22-23, NCL was the leading subsidiary of CIL, with the highest OBR of 463.40 million cubic metres.

To support sustainable mining, NCL has established an Over Burden to Sand Making Plant in the Amlohri area. This sand, which comprises 60 per cent silica, can be used as building material in civil works and may be used as an alternative to river sand. “We have set up a pilot project of the unit with a sand generating capacity of 2,000 cubic metres per day and are planning units like these in four more locations. We call it wealth from waste,” Singh explains.

Driven up by environmental concerns and the depletion of open cast mines, CIL is focusing on unlocking its untapped underground reserves. Underground coal is known for its superior quality and environment-friendly mining practices, making it a viable alternative to more expensive imported coal. “Earlier the production cost in underground mining was

5-6 times higher than in open-cast mining and also more labour-intensive. But with new technology and advanced machinery the cost has become viable. By 2030, 100 MT of good quality coal should be extracted from UG mines as against only 25 MT at present. It has become the trend today,” says Reddy.

CIL has introduced 24 Continuous Miners in 18 UG mines with a total production capacity of 10.50 MTY. There are plans to deploy 42 more Continuous Miners in 20 mines by March 2026. Additionally, four Powered Support Longwall (PSLW) equipment are proposed to be installed by March 2027.

CIL is also adopting business models like mine developers and operators as well as outsourcing operations. Progress is underway for reopening 30 discontinued mines that have estimated mineable reserves of around 600 MTS.

“We have been actively using underground mining for mass production. By using this technology, Coal India has now understood its importance. The process will also reduce coal imports. Today, China produces 90 per cent of their coal through underground mines out of their total production of 4 billion MT,” says Agrawal.

Talking about the entry of private mining companies, Agrawal thinks it is a good decision by the government. He says: “This would help the country reduce coal import dependency to some extent. Also, in CIL, we have so far been working in a protected environment. With the entry of private players, CIL will become more efficient.” Indeed, it is rumoured that the government may sell a small stake of 3-4 per cent which should realise Rs4-5,000 crore.

The country imports a total of 215 MT of coal. There are certain types of coal like coking coal for steel-making through the blast furnace route, which will always be import-dependent. At least until another method is developed such as using an arc furnace or gasification. Also, some high-grade coal is required for cement production.

In the wake of forecasts that a hot summer may push up coal demand, CIL is gearing itself to meet this requirement on the back of adequate coal stocks at its pitheads and increased production in the first quarter of FY24. “Meeting coal demand in summer is a big challenge. Coal shortage is unlikely this time. The coal available in the system is adequate,” says CIL marketing director Mukesh Choudhary.

Even after considering any unforeseen surge in demand from the power sector, the quantity to be supplied to NPS will still be significantly higher compared to the 109 MT supplied in FY22.

-

Ranjan: wage hike will benefit non-executive workforce of 2.38 lakh; Pix: SAJAL BOSE

However, the outstanding coal sale dues from government-owned power plants are a major issue for CIL at present. It reached over Rs16,500 crore in FY23. “It is a matter of concern for us. There is a coordinated effort at all levels to scale it down,” says Choudhary.

Diversification initiatives

Debasish Nanda, Director of Business Development, says: “We are exploring several diversification initiatives, which include pit-head thermal power generation, solar projects, the aluminium business value chain, and coal-to-chemicals through Surface Coal Gasification. The strong growth in automobiles, construction, and the power sector has increased over the past decade. Considering the demand for aluminium, we are stepping in to set up an integrated aluminium smelter plant in Odisha.”

CIL recently increased wages across all levels of its non-executive workforce of 2.38 lakh. The Joint Bipartite Committee for the Coal Industry (JBCCI)-XI, consisting of representatives from CIL management, Singareni Collieries Company Limited (SCCL), and five central trade unions (BMS, HMS, AITUC, CITU) and Indian National Mine Workers’ Federation (INMF)), recommended and signed the National Coal Wage Agreement (NCWA)-XI for a period of 5 years, effective 20 May, 2023.

“Under the agreement reached, a 19 per cent minimum guaranteed benefit from 1 July, 2021, on emoluments (basic, VDA, SDA & attendance bonus), and a 25 per cent increase in allowances have been granted,” says Vinay Ranjan, Director of Personnel and Industrial Relations.

As the second-largest employer after Railways, the state-owned coal miner is gradually reducing its workforce through natural attrition by 10,000-12,000 employees every year, says Ranjan. It also outsources manpower, with 75 per cent of coal evacuation being outsourced.

“When I joined CIL, it used to produce 600 MT. So, I am leaving CIL slightly better than what it was,” says Agrawal. According to him, in the next 5 years, CIL should focus on increasing production, investing in modernisation and digitisation, and finally diversifying for the future. “I think with its inherent expertise in mining, CIL should also consider mining other minerals. Perhaps that will provide Coal India with a viable option even after 30 years,” Agrawal concludes.

-

Prasad: Production, OBR, total supplies, supplies to power sector and profitability have reached all-time highs

Sustaining the tempo

PM Prasad, the current CMD of Central Coalfields Limited (CCL) is set to become the next chairman of Coal India L(CIL) in July. With a postgraduate degree in coal mining and three-and-a-half decades in the field, he brings a wealth of knowledge to the table. Under his leadership, CCL achieved the production target for the first time in its history. Prasad also had a three-year stint in NTPC. In an interview with Business India, he discussed his immediate challenges and priorities at CIL.

CCL has for the first time achieved its production target in FY23 and continues to put up a strong show with over 11 per cent growth. How was this achieved?

Eclipsing the target of 76 MTs was a result of synergy on multiple fronts. Of the 13 areas under CCL’s command, 8 areas have exceeded their respective targets, ramping up the output. They also filled in the shortfall of 5 other areas. Land being a major pain-point, persistent follow-ups with district and state level authorities resolved the issues to some extent. Environmental clearance of 30 MTs was obtained during FY23 while forestry clearances for 1,322 hectares of land were given the go-ahead. The outsourcing of contracts and addressing various grievances were other contributing factors.

The 1 billion tonne target is yet another challenge. As an incoming incumbent what are your plans to achieve this?

We will approach it in a two-pronged manner. Firstly, capacity augmentation through expansion of existing mines and secondly operationalisation of greenfield projects. A total of 52 coal mining projects have been approved which will incrementally contribute an aggregate of 378 million tonnes per annum in a phased manner. These will contribute incremental projected production of 102 MTs in FY25-26. Of the 52, greenfield projects make up 13 and the balance 39 are expansion projects.

MCL, SECL and CCL will be significant contributors towards the challenging goal. Our pursuit of the MDO (Mine Developers and Operators) model will also uplift this endeavour. Of the 15 MDO projects with a combined targeted capacity of 170 MT/y work orders were issued for 12 projects of 134 MT/y capacity and production has begun in three projects. Fast-tracking land, EC and FC clearances is another priority area.

Concurrent with production, establishing an increased evacuation infrastructure is equally important. Your comments.

Rail remains the preferred mode, with 52 per cent of our coal moved on tracks. To strengthen rail evacuation logistics CIL is constructing 21 additional greenfield and brownfield railway sidings in four subsidiaries. Seven of them are already commissioned and the rest are being pursued for operationalisation by FY25. We are also refurbishing old sidings. Twenty-four rail connectivity projects are being consolidated between the sidings and the main rail lines, of which five are commissioned.

The integration of existing and new rail sidings with a combination of CHP and Silo projects will help to improve loading quantity. We are also funding seven railways projects with a combined length of 621 km to be operational by December 2026. Of these four are JVs with Railways and three are on a deposit basis.

-

Carbon footprint suppression would be sizeable in FMC

What are your goals and priorities?

Obviously, to sustain the tempo set in motion during FY23. Production, OBR, total supplies, supplies to power sector and profitability have reached all-time highs. These have to be taken forward without any let-up, in order to better physical performance and protect the bottom line. On the supply side, ensuring uninterrupted coal flow to the power sector is a top priority. This fiscal we are also confident of satiating the coal appetite of the non-power sector. Ensuring the high quality of coal is an equally important priority area.

Coal India was a late starter in venturing into renewables. But it has stepped up. What are you plans to take this initiative forward?

Coal production is our core competence and our foray into renewable energy is driven by net-zero commitments. Also, solar power will replace coal as a key energy provider in the future and we are laying the groundwork to remain relevant and retain our leadership in the country’s energy sector. Although there have been initial hiccups, we now have concrete plans which are picking up pace.

We are aiming at 3,000 MW of solar power projects by FY26. For this year we have kept a target of 400 MW of which EPC (engineering, procurement and construction) contracts have been awarded for 300 MW while the remaining projects are in the tendering, approval and award stage. For the ensuing 2 financial years we will be taking on solar projects of 1,143 MW and 1,158 MW capacities respectively.

-

CIL coal mine: highly mechanised; Pix: SAJAL BOSE

History of Coal India

The nationalisation of the coal industry in India in the early 1970s was a result of two related events. Firstly, it was triggered by the oil price shock, which prompted the country to carefully examine its energy options. A Fuel Policy Committee was established for this purpose, and it identified coal as the primary source of commercial energy. Secondly, the required investment for the growth of this sector was not forthcoming, as coal mining was, for the most part, in the hands of the private sector, which prioritised profit over mine safety.

The control of coal mines in India was taken over by the government in two stages during the 1970s, in line with the National Energy Policy. The Coking Coal Mines (Emergency Provisions) Act 1971 was enacted on 16 October 1971, through which the government took over the management of all 226 coking coal mines, except those owned by IISCO, TISCO, and DVC. These mines were nationalised on 1 May 1972, leading to the establishment of Bharat Coking Coal Limited (BCCL).

Furthermore, with the promulgation of the Coal Mines Ordinance 1973 on 31 January 1973, the Central Government took over the management of all 711 non-coking coal mines. After this, a public sector company named Coal Mines Authority Limited (CMAL) was formed to oversee these non-coking mines.

In November 1975, a formal holding company called Coal India Limited was established to manage both BCCL and CMAL. Coal India Limited (CIL) emerged as an organised, state-owned coal mining corporation, with the government taking over private coal mines and forming a total of five subsidiary companies. Four of these companies were involved in coal production, while the fifth focused on mine planning and consultancy.

The four coal producing companies were: Eastern Coalfields Limited (ECL) in Sanctoria, West Bengal, Bharat Coking Coal Limited (BCCL) in Dhanbad (now Jharkhand), Central Coalfields Limited (CCL) in Ranchi (now Jharkhand), and South Eastern Coalfields Limited (SECL) in Chhattisgarh. The mine planning, design, exploration, and consultancy company was Central Mine Planning and Design Institute Limited (CMPDIL) in Ranchi (now Jharkhand).

There was a reorganisation in 1986, resulting in the formation of Northern Coalfields Limited (NCL) in Singrauli, Madhya Pradesh, which included the mines previously under the command area of CCL. Subsequently, South Eastern Coalfields Limited (SECL) in Bilaspur, Chhattisgarh was established by incorporating mines from Central Coalfields Limited and a few mines under WCL. This brought the total number of subsidiary companies to seven, including six coal producing companies and CMPDIL.

In April 1992, Mahanadi Coalfields Limited (MCL) was formed in Sambalpur, Odisha, incorporating mines under the command of SECL, particularly in the Talcher coalfields and the Ib Valley. North Eastern Coalfields (NEC), a coal producing unit directly administered by CIL, operates in Margherita, Assam. Dankuni Coal Complex in Dankuni, West Bengal operates under the command of SECL. Presently, CIL is the apex body with seven wholly-owned coal producing subsidiaries and one mine planning and consultancy company, operating across eight states in India.

In 2010, the government decided to disinvest 10 per cent of equity in CIL. The Initial Public Offer (IPO) of Coal India was a significant undertaking considering the size of the company. It was oversubscribed 15.3 times. On 11 April 2013, the Government of India granted CIL Maharatna status.