-

Jaipuria: leading from the front

Opportunities in adversities

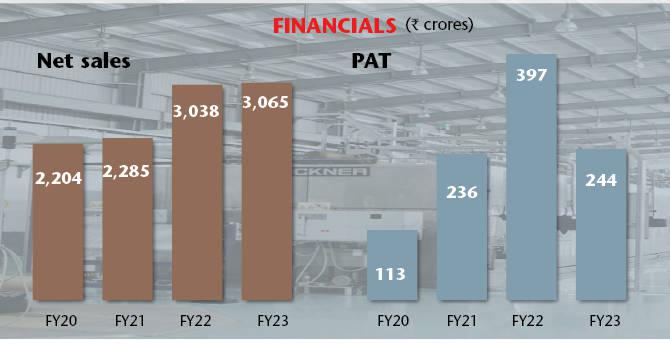

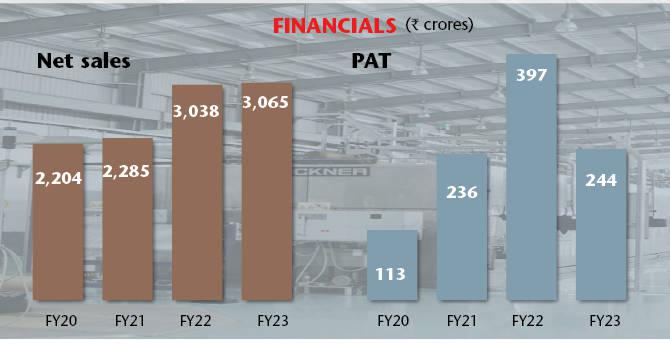

Having grown at CAGR of over 13.3 per cent during FY18-FY22 (where speciality film sales recorded a CAGR of 18 per cent over 3 years), Cosmo First saw its consolidated revenue growing marginally to Rs3,063 crore in FY23 from Rs3,038 crore in FY22. The PAT during the period was down to Rs244 crore from Rs397 crore.

Experts are of the view that during FY23, the BOPP and BOPET industry faced excess supply due to the bunching of new production lines resulting in declining contribution margins each quarter during FY23 and impacting the entire industry. Despite this Cosmo continued to outperform and post double-digit EBITDA primarily due to its 62 per cent speciality film sales during FY23. While the near-term BOPP & BOPET outlook remains challenging, the company’s focus on speciality films for BOPP and BOPET should keep it at the forefront.

During FY23, the company’s subsidiary which dealt in Specialty Chemicals (which started its operation in 2021 with a masterbatch line) did an overall sale of Rs159 crore, which is 75 per cent higher compared to the previous year. Cosmos reached almost 75 per cent capacity utilisation on its master batch line.

Masterbatch is a concentrated mixture of pigments and additives used for imparting specific desired properties and colouring in plastic. Besides, the complementary adhesives business for packaging segment is set to grow in the current financial year. The company is expecting to end the current year with a topline of over Rs200 crore and is aiming at Rs500 crore in the next 3-4 years.

In speciality chemicals, the company has three verticals: masterbatch, coating chemicals and adhesive. While masterbatch (capacity: 10,000 tonnes) and coating chemicals (5,000 tonnes) went operational last year, adhesive (capacity: 2,500 tonnes) is expected to commence commercial production in the current fiscal year. In each of these segments, it plans to cater to to address current problem areas in the industry or produce a significantly better product compared to that currently available.

In order to explore the fast-growing Rs5,000-crore domestic pet care market, Cosmo First launched its D2C pet care vertical under the brand Zigly in September 2021. In a short space of time, the business has made good progress. Besides online sales, the company has 15 experience centres as of March 2023 and is looking at increasing this to 100 of them in the near future. It also offers services such as pet grooming, veterinary care and behaviour training.

The current monthly GMV for Zigly is close to Rs2 crore, and Cosmos is targeting 10 times this amount in the next couple of years. In FY23, GMV for the Zigly division stood at Rs13 crore, which was 9 times more than the previous year. The company is looking to cross Rs50 crore during the current year and around Rs100 crore by next year. The Rs5,000-crore domestic pet care industry is growing at a CAGR of 25 per cent.

“The company’s strategic diversification into emerging sectors such as speciality chemicals and pet care has been growing as envisioned. Both segments are expanding and contributing to its long-term potential for value creation. To fuel the growth in speciality chemicals, the company is going to launch adhesive during the current year for its existing B2C customer base. In the pet care segment, future plans include increasing the experience centres to 100+ in a couple of years besides promoting an online business,” says Jaipuria.

-

A visionary entrepreneur, Jaipuria founded Cosmo First in October 1976 and set up the first BoPP production plant of ٨٠٠ tonnes at Aurangabad, Maharashtra in ١٩٨١. In fact, he introduced BoPP films to the Indian market through the launch of Cosmo Films (as it was then known). Today, the company has emerged as a leading name, providing pioneering niche solutions (value-added BoPP films) in packaging, lamination, industrial and labelling applications. The offering includes a range of BoPP films, CPP films and BOPET films.

Innovative solutions

Backed by a workforce of over 1,100, the company has four manufacturing units in Aurangabad, Maharashtra (two facilities), Vadodara and South Korea. Apart from its BoPP capacity of 196,000 tonnes per annum (9 lines), it has capacities for specialised BOPET (30,000 tonnes); CPP (10,000 tonnes); thermal films (40,000 tonnes); coated specialised films (20,000 tonnes); metalized films (22,000 tonnes) and CSP (7,0000 tonnes). CSP or Cosmo Synthetic Paper is a direct replacement for pulp-based paper wherever durability is desired. It is a co-extruded, white opaque polypropylene-based synthetic film that looks like regular paper.

In the last fiscal year, Cosmo started commercial production of its specialised BOPET Line which is the world’s largest line for shrink labels and heat control films. During the year, it incurred a total capital expenditure of around Rs380 crore as compared to Rs285 crore in FY22.

The company has recently entered into an agreement to source renewable power on a group captive basis. Accordingly, about 40 per cent of power requirements for the company’s largest plant will be from renewable sources. In the near future, it will be targeting close to 50 per cent of its power requirement from renewable sources.

With innovation at its core, the company invests heavily in R&D to come up with high-value specialised products and thus stay ahead of the curve. It currently has eight registered patents with three in the pipeline and another eight are being applied, Cosmo First’s Innovation Centre is a state-of-the-art facility that boasts world-class laboratories, serving as a vital asset to the company’s operations. The centre is equipped with cutting-edge equipment and manned by a team of 30-odd highly qualified professionals dedicated to sustainable and economically viable science.

The analytical lab at Cosmo First’s facility is at the forefront of material characterisation, thanks to its array of modern equipment. The lab is well-equipped to perform microscopic analysis, which allows researchers to understand the finer details of the material’s chemical and physical properties. In addition, the lab boasts of advanced thermogravimetric analysis (TGA) equipment, which enables scientists to investigate the material’s thermal stability and degradation characteristics.

“We take great pride in being one of the few packaging companies globally with such a robust R&D set-up. Our R&D endeavours have resulted in the creation of several new products, which have significantly contributed to our growth and success. Our focus on innovation and R&D has enabled us to stay ahead of the curve and maintain our position as an industry leader. With our modern facilities and world-class research team, we are continuously pushing the boundaries of what is possible in our industry,” avers the Cosmo First chief.

-

Poddar: a turnaround specialist

Backed by its R&D efforts, Cosmo First has a strong focus on sustainability and invests heavily in promoting innovative practices to come up with products and solutions that are environment-friendly. The company has been partnering with some of the best global brands to offer structure rationalisation. It is engaged in creating monolayer, mono-material structures, which are easily recyclable.

The company has designed heat-resistant BoPP films replacing BOPET; it is mainly used in the print layer, giving a last push to the creation of mono-material structures. Both BoPP and CPP films offer better yield, hence enable reduced consumption of plastics. It promotes UV stabilised synthetic paper that can be used to replace PVC in outdoor promotional applications for a shorter duration. Besides, the company offers a suitable substitute for aluminium foil in the form of its ultra-high barrier films.

“Cosmo First has a strong focus on sustainability. We work closely with large global brands to design and manufacture products that are not only eco-friendly but sustainable in the longer run. The vision of Cosmo First is that the company aspires to be recognised among the most innovative businesses, developing high-growth businesses that are sustainable, scalable and profitable,” says Poddar.

Sustainable packaging

Cosmo First has carved a distinct niche for itself in the packaging market where it competes with names like Jindal Poly Films, Uflex, Polyplex and others. The packaging industry has evolved significantly in the past few years, something induced by the pandemic. Through the different phases of the pandemic new trends have emerged and have been adopted by various companies in the packaging industry.

From smart packaging to sustainable and safe packaging with innovation and an artistic touch, packaging trends have gained a lot of prominence in the food, pharmaceutical, beverage, cosmetic and other FMCG industries. The large FMCG players globally have announced moving to sustainable packaging in a phased manner and this is where Cosmo First with its innovative solutions plays a major role.

The global packaging market, valued at $1,002 billion in 2021, is expected to reach $1,275 billion by 2027, registering a CAGR of 4 per cent. The global flexible packaging market which stood at $125 billion in 2021, is expected to reach $164 billion by 2027, growing at a CAGR of 4.5 per cent. As against this, the Indian packaging industry, which is one of the largest globally, is expected to register a CAGR of 27 per cent during 2022-2027, while the flexible packaging market in India is set to grow at a CAGR of about 11 per cent during 2021-2025.

-

End-user industries like pharmaceutical, food processing and personal care are expanding with huge investments from large multinational corporations. This has resulted in developing cheaper and sustainable packaging solutions which are fuelling the expansion in the packaging sector. Additionally, factors like increase in the working population that require instant food solutions with higher shelf-life have forced packaging companies to come up with innovative and durable packaging solutions.

With all these developments in place, Cosmo First has positioned itself quite strongly in the market. A pioneer of BoPP firms in India and currently one of the largest manufacturers of BoPP films for flexible packaging, the company has stayed ahead of the curve and moved from making commodity films to innovation-led specialty films. Today, speciality products and solutions account for almost 60 per cent of its portfolio, up from around 25 per cent around 3-4 years ago. In fact, it is aiming to enlarge the share of specialty films to 80 per cent in the next couple of years.

Moreover, the company is also ramping up its capacity in a big way. The combination of scaling up and diversification into specialised firms will help it build a robust portfolio which will facilitate its next growth phase. Moreover, going forward consumer-facing newer businesses will provide the total business further scale and diversification.

-

Cosmo is a pioneer in the BOPP film industry in India

Innovative Product Launches

• Direct Thermal Printable Film: Film specially designed for niche applications like information labelling (airport baggage tags), inventory tracking, frozen food labelling & parking ticket applications.

• High Scratch Resistant Metalized Film: Specially designed for pressure sensitive label stock applications, the film delivers spectacular print performance across a wide variety of printing processes like flexography, silkscreen, foiling etc.

• 100% Opaque Synthetic Paper: Non-tearable, co-extruded, white opaque and both sides matte coated film for dangler application

• High Tear Resistant Synthetic Paper (CSP): Originally designed for high tear resistant tag applications. Also offers moisture, oil and chemical resistance just like standard synthetic paper.

• Enhanced Barrier Metalized BOPP Film: Suited for packaging of biscuits, snacks, bakery products, chocolates and personal care products like shampoo sachets etc.

• White Cast Polypropylene (CPP) Film: To address the issue of slippage of layers over each other as having high Coefficient of Friction (COF).