-

The company is the second largest manufacturer of aluminium flat-rolled products

Equipped with 11 aluminium extrusion presses, the company, backed by over 2,500 employees, has a modern tool shop capable of producing high-quality and intricate dies, backed up by an international quality billet casting facility. JAL, with extrusion facilities across two locations: Bengaluru and Dabaspet near Bengaluru, has led the industry in installing technological and modern equipment in order to obtain high quality aluminium profiles. The company boasts of presses ranging from 750 UST to 4,000 UST capacity, even as it has put up a billet casting facility (hot top casting) imported from the US and a modern tool shop equipped with the latest CNC, EDM wire cut and other ancillary equipment.

JAL’s aluminium flat-rolled products plant at Dabaspet is equipped with the latest equipment for producing aluminium sheets, coils, foils, circles and other flat products in various alloys and thicknesses. The facility has a captive foundry, holding furnaces and casters for making quality products ranging from 0.009 mm to 5 mm in thickness.

Worldclass facilities

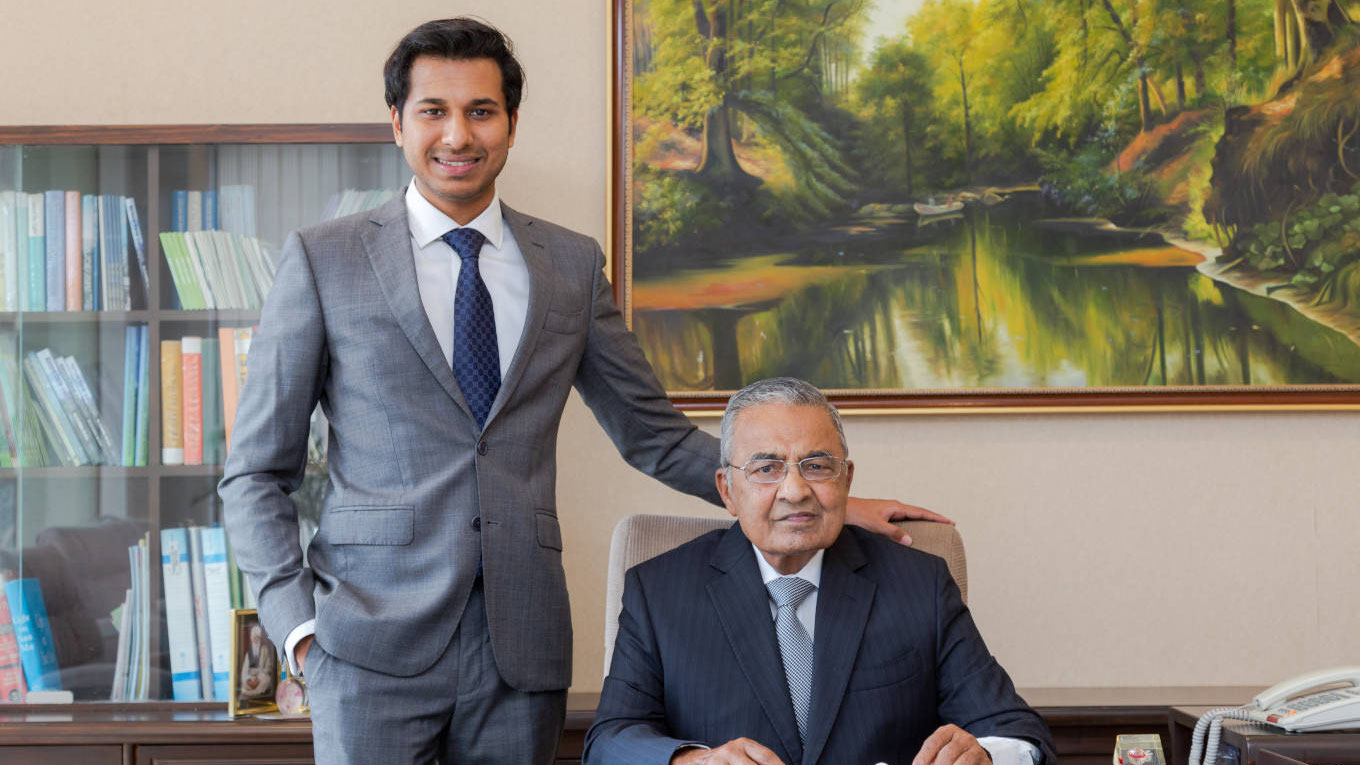

“We have set up world class manufacturing facilities for manufacturing a wide range of extrusions and flat-rolled products. Committed towards quality, we continuously strive for customer satisfaction. In our five-decade-old journey, we have been associated with some of the world’s finest companies in their growth and success. In fact, our company has elevated the status of aluminium. We have done so by designing and manufacturing innovative value-added aluminium products and solutions for a broad range of applications,” says Pragun Jindal Khaitan, 29, vice chairman and managing director, JAL.

“We have invested in technology and quality to set the industry benchmark. Looking back with the benefit of hindsight, I am pleased to see success in the form of being India's largest extruder,” says Sitaram Jindal, 88, founder and chairman, JAL.

Coming from a family which decided to get into business (from being in farming in Hisar, Haryana) in the 1950s by setting up a manufacturing factory for steel pipes, bends and sockets at Liluah near Kolkata (and thereafter a large steel pipe factory, Jindal India Ltd, in Hisar), Jindal envisioned a future beyond steel and wanted to do something that could lay the foundation for another vital industry (aluminium was a relatively new metal at that time but held a lot of promise due to its inherent characteristics).

Since the Karnataka government was offering incentives for industries, he decided to move out of Kolkata and laid the foundation of the present Jindal Aluminium Ltd, by setting up an aluminium extrusion facility in Bengaluru. Apart from supportive state government policies, the then Madras-based public sector Malco (now part of Vedanta Resources) readily provided a free flow of the raw material, procured from Orissa, which had an abundant supply of aluminium. Also, in Bengaluru, land was cheaper and aplenty, and there was an ample supply of electricity as well.

Born to Netram Jindal and Chandravali Devi on 12 September 1932 in the remote village of Nalwa in Hisar, Haryana, Jindal was the fourth of five brothers (Devisahay, Bhavichand, Om Prakash, Sitaram and Madanlal) all of whom later became well known and carved niches for themselves in different businesses. Om Prakash Jindal, who passed away on 31 March, 2005, established a successful business enterprise – Jindal Steel and Power – under the flagship of the Jindal group, of which he was the chairman. Om Prakash’s four sons, Prithviraj (Jindal Saw Ltd), Sajjan (JSW Steel), Rattan (Jindal Stainless) and Naveen Jindal (Jindal Steel and Power) are well known names in the industry.

-

The company has a dedicated quality system for checking the quality of the products

With grit and determination, Jindal, the younger brother of Om Prakash, put up the country’s largest aluminium extruder which has continued to maintain its leadership in the downstream aluminium sector. For the last decade or so, he has found able leadership in his grandson, Pragun. Having joined the business as a wholetime director, Pragun was elevated as managing director of the company in 2017, even as Jindal took a backseat, overseeing the business. In 2020, Pragun was given the additional responsibility of vice-chairman of the company.

Jindal spends quality time in various social and charitable activities. He was instrumental in establishing and running several charitable institutions in the field of education, health and social welfare. Sitaram Jindal Foundation, the erstwhile SJ Jindal Trust established in 1969 by Jindal, is one of the leading NGOs in the country. Besides, his real passion also lies in the great elemental forces of nature and their curative and sustaining powers. The blossoming of this interest led him to create Jindal Naturecure Institute, a world-renowned Naturopathy and Yoga hospital set up on 115 acres on the outskirts of Bengaluru in 1978.

“My grandfather is a true visionary. He could foresee the potential of aluminium which was still a new metal. Getting into a completely new business and, that too in a new location, was definitely a challenge. But he did it and made a distinct mark for his business. He always believed in adopting newer technologies and manufacturing quality products that live up to customer expectations. At JAL, we are all constantly working towards pursuing this vision,” says Pragun, who has put up a roadmap to grow the company at a CAGR of 15 per cent in the next 10 years, even as it has grown at a CAGR of around 10 per cent in the last five years.

In the last fiscal year, the company, owing to Covid-related challenges, saw its revenue marginally down to Rs2,887 crore from Rs2,965 crore in the previous year. While the domestic market was sluggish, the company managed to make up some of this in the exports market where its sales doubled to 20 per cent as compared to that in FY20. Last year, the company produced 80,409 mt of extrusion products, 34,609 mt of rolled products and 927 mt of powder coating.

Expanding capacities

The company began 2020 by installing the fifth caster in the rolling division, thus increasing the overall flat-rolled products production capacity by 25 per cent to 50,000 mtpa, even as it has plans to increase it further to 75,000 mtpa going forward. The company has invested Rs100 crore in this expansion project.

-

Apart from expanding our capacities to meet the growing market needs, we are also upgrading the existing facilities and putting up newer technologies for increasing the share of value-added products in our total production basket

JAL has installed a 1,650 mm width cold rolling mill in its state-of-the-art plant. This is a modern, high-speed mill, manufactured by Zhuoshen, China. It is equipped with an automatic gauge control system to maintain the output thickness as per the required specifications. “We have also installed an X-ray gauge checking system by Mesacon, Germany and an automatic flatness controller system from Achenbach, Germany, due to which the products match any international standards required by the most demanding applications,” says Naveen Mehta, President, Operations, JAL.

The company has adopted the latest technologies in its foundry, which offers its aluminium profiles superior surface finish, and good chemical and mechanical properties that meet international standards. Similarly, the in-house tool shop ensures superior quality dies which are being used to produce intricate customised designs. The company has a dedicated quality system for checking the quality of the products. Starting from the testing of inward raw material to the final inspection before dispatch of its extrusions, the QA team ensures the products exceed customer expectations in all parameters.

“Our operations are managed by qualified and experienced engineers in consultation with German and American technical experts. With more than 8,000 different shapes of profiles, we have the capacity to produce profiles as wide as 425 mm, depending upon the shape, size & CCD,” adds Mehta.

With a capex of around Rs90 crore, the company has also installed a foil rolling mill for making foils upto 0.009 mm thick in its state-of-the-art unit made by Achenbach, Germany. The foil mill has the best integrated process control, automation and drive systems available in the industry. The mill is equipped with an auto flatness controller system, due to which the products exceed any international standards required by the most demanding applications.

Moreover, the company has recently also put up a one of its kind environment-friendly powder coating facility (project cost; Rs10 crore; capacity: 700 mt per month), capable of achieving 1/1,000 mm level of accuracy. This powder coating line is equipped with a technology that ensures uniform colour coating for the extruded products.

“Apart from expanding our capacities to meet the growing market needs, we are also upgrading the existing facilities and putting up newer technologies for increasing the share of value-added products in our total production basket,” states Pragun who has been instrumental in driving the growth of the company in the last few years.

Like his grandfather, he is aggressively looking to imbibe the latest technologies and processes, and today JAL is all geared up to begin its next growth phase in a market which has undergone a transition as consumers have become more discerning in nature. He has successfully stabilised production at JAL’s aluminium flat rolled products plant, taking it from inception to being the second largest supplier of aluminium flat rolled products in India within a span of five years. During this time, he also restructured the management team of the various businesses and brought in outside talent to fill in the new positions that he created.

-

The company has set up world class manufacturing facilities

Having completed his higher secondary education from Sevenoaks School, UK, Pragun went to the US for higher studies and completed his bachelor’s degree in Economics at Wharton Business School. Before joining JAL in 2013, he worked towards setting up the Thiruvananthapuram branch of the world’s pioneering microfinance institution, Grameen Bank, during his internship in 2009. Pragun is married to Sukriti Jindal Khaitan, daughter of Sanjay Kothari who is vice chairman and the fourth generation of the founding family of the global diamond and gemstones giant, KGK Group.

Diversification drive

“JAL and the Indian downstream aluminium industry have aligned themselves to support the government’s push for Atmanirbhar Bharat. With a progressive infrastructure push, we foresee an upsurge in aluminium consumption in our country from the current level of 2.5 kg per capita, which is much lower than the global average of 11 kg per capita. The downstream aluminium industry that JAL is a part of, has extensive forward and backward linkages to the economy and policy reforms can reduce our import dependency and help make us contribute towards self-reliance,” says Pragun who has also carried out the group’s diversification drive.

The group has successfully ventured into real estate with a strategic partnership with the Prestige Group to develop one of Bengaluru’s landmark projects on its land bank of around 300 acres in and around Bengaluru. The JV is constructing a futuristically-designed township: Prestige Jindal city (around 3,500 residential units) on 32 acres off Tumkur Road in Bengaluru.

Moreover, Pragun’s passion for sustainability and clean energy has seen the country’s largest extrusion maker get into renewable energy in a big way. Under a separate vertical, the company currently produces 80 MW through wind and solar power plants. This has not only made it 100 per cent self-sufficient for its energy needs, but has also led it to supply almost 50 MW of surplus energy to the grid annually.

-

Newer technologies help increase the share of value-added products

“Pragun has played a vital role in creating a niche for the company and making it an entity to reckon with. He knows everything about aluminium and is a strategist of some consequence. It has been his idea to diversify the group’s activities into different sectors including renewable energy and real estate. He keeps abreast with the latest technology in the field and wants the company to invest in technology upgradation and capacity expansion,” says Jindal.

Experts believe that the demand for aluminium across industries will continue to surge. The key lies in the weight difference that aluminium can offer. Aluminium clearly wins when it comes to lightweight, which is a key parameter today for automobile manufacturers. It is a metal that made aerospace a reality. Being a metal that is universally versatile, aluminium finds itself widely used across various sectors due to its sustainable nature, and energy-efficient qualities.

“Aluminium is an industry-friendly metal used in industries for decades due to its mechanical and other properties such as its lightweight and tensile strength. The aluminium industry in our country can witness a strong growth prospect in the upcoming years. While the national aluminium demand has been rising at the rate of 10 per cent every year, it is predicted that aluminium consumption will double in the subsequent five to seven years,” states Mehta.

With all these developments in place, JAL has positioned itself quite strongly in the aluminium downstream market which will continue to witness a surge in demand from multiple industries. Aluminium, due to its inherent characteristics, is expanding its application spectrum and this is where a player like JAL will maintain its leadership position. Having led the industry with pioneering efforts, the company, over the years, has consistently upgraded and innovated, adopting newer technologies and processes. There are constant efforts to come up with value-added products in diversified industries and this has helped the company in not only improving margins but also expanding the topline.