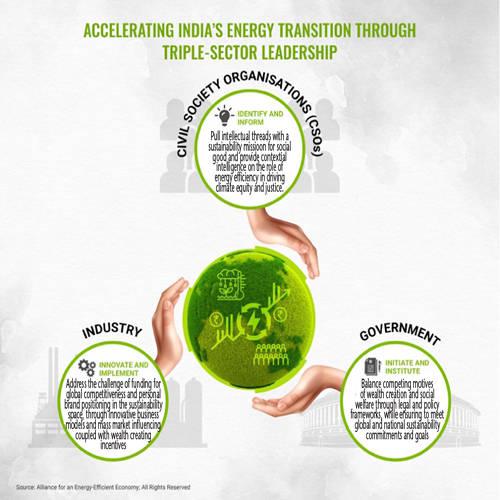

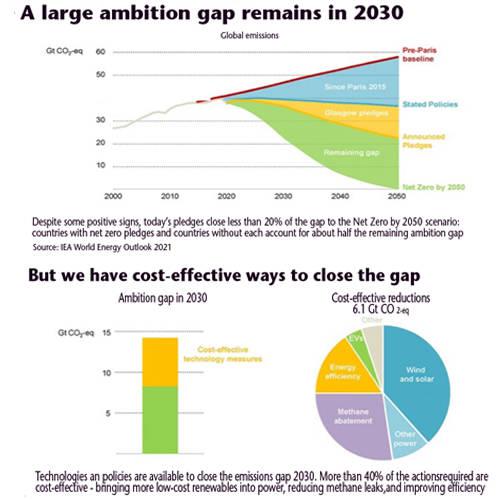

How do you start to solve the biggest challenge facing mankind? Of course, by working together and creating an inter-dependent system of innovative business model, aggressive policies and creating a low carbon culture in our society. As the infographic below shows, a problem as complex as climate change can only be solved through triple-sector collaboration where government, industry and non-profit organisation needs to work collaboratively, synergistically, and persistently to solve the problem. A recent example worth emulating is the progress and solutions that have been made under Montreal Protocol where the global triple-sector community has come together to solve ozone depletion challenge initially and more recently global warming challenges as a result of the use of refrigerants – a lifeline for the modern world in a warming planet. Energy at the heart of climate change challenge: In its 2021 World Energy Outlook report, International Energy Agency has voiced concerns that today’s pledges by all countries close less than 20 per cent of the gap to the Net Zero by 2050 scenario – an equilibrium state that many climate scientists and policy makers believe is needed to counter the threat of climate change in a meaningful manner. At the same time, IEA also unequivocally says that demand side interventions in the form of energy efficiency, which it calls the first fuel, is one of the most cost-effective technology measures available today to help bridge the ambition gap. Why is this so significant? Energy efficiency remains the cheapest, fastest and cleanest form of interventions not only to move from pledge to action but also to create a thriving business ecosystem that will help create India an energy-efficient economy with millions of green jobs, new start-ups deploying latest digitalisation, artificial intelligence and machine learning techniques that can make our appliances more energy efficient, buildings more thermally comfortable and sustainable, industry more globally competitive and our cities and urban landscape cleaner, greener and more people friendly. Embodied and operational energy Energy is consumed twice by most appliances, buildings, vehicles, smartphones, etc. that are the staples of people living in the modern world. The first is the embodied energy that is used to manufacture or build these objects and the second is the energy consumed by these objects themselves. So, Tata Steel, ACC Cement, Hindalco, Maruti Auto, Vedanta etc. all play a very important role in producing either the raw materials or the widget themselves; their process efficiency and the energy intensity (Joules/tonne of steel or cement or Joules/Maruti Swift for example) will have a huge bearing on the embodied energy of cars or appliances or homes that we build today. While there is increasing pressure to quantify the energy or carbon intensity of the products, it is a non-trivial task to capture energy consumed during the entire lifecycle of manufacturing. Yet, companies are facing the pressure either from the environmentally conscious governments as they enact policies such as Extended Producer Responsibility which is holding the manufacturers responsible through cradle to grave or production through disposal/recycling of the products or by shareholders asking the companies to report quantitative data showing how well they are doing on the Environment-Social-Governance (ESG) framework. Since ESG performance is starting to affect the share price of companies as institutional investors such as pension funds, etc. are asking for more transparency and standardised metrics to show how efficient their manufacturing processes are. Suddenly, circular economy and resource efficiency are no longer fancy buzzwords reserved for avant-garde companies but are being discussed in the board rooms of majority of the Fortune 500 companies.