-

Singh: moving up the value chain

In another significant move, STIL recently achieved the significant milestone of becoming one of the few large Indian textile companies to have integrated the backward manufacturing of ‘green’ fibre. With an aim to transform the company into a sustainable entity, the company initiated the production of Polyester Staple Fibre (PSF) with an investment of R225 crore by recycling PET bottles. This facility, located in Baddi, Himachal Pradesh, can produce 120 tonnes of recycled PSF per day. It was commercially launched in March 2021. The company consumes over 85 per cent of its green-fibre capacity for its captive requirements.

“As a company, we have kept on evolving with the times. We have set our sights on emerging as a front-runner in the realm of global textiles by providing end-to-end solutions – from fibre to yarns to home textiles. We aim to create maximum value for our customers so as to emerge as their partner of choice. The company’s philosophy is about being patient and persevering in the face of challenging market realities. It is about empowering employees to respond with initiatives that strengthen the business. It is about the coming together of sustenance and empowerment leading to sustainable growth,” says CS Nopany, 57, executive chairman, STIL.

“The validation of this ethic is reflected in the longevity of our company. The fact that we have survived and succeeded in this challenging space across political, economic and technology cycles is a vindication of our commitment to perpetually expanding capacities and capitalising on economies of scale, investing in ongoing modernisation to enhance operating efficiencies, and deepening a culture of innovation with the objective of bringing differentiated products to consumers,” adds Nopany.

Getting future ready

A chartered accountant who holds a Master of Science in Industrial Administration from Carnegie Mellon University, Pittsburgh, USA, Nopany inherited the company from his maternal grandfather Krishna Kumar Birla. He is the son of Birla’s eldest daughter Nandini, and Bimal Kumar Nopany. He joined the family textiles business way back in 1994 and was eventually appointed as its chairman in 2008. He played a major role in the transformation of this legacy company into a robust and future-ready entity.

“We are moving up the value chain, which is also bringing us closer to retail consumers. Today, we work closely with our customers. We believe in challenging our limits and overcoming them. We also believe that as time changes, one must evolve. Today, we as an organisation have become more robust and also more agile to adjust to the fast-changing market requirements. We are also focussing on our people through multiple initiatives so that they work as a more cohesive team. Moreover, over the last few years, we have strived to be a responsible corporate, reducing our carbon footprint by investing in green technologies and sustainable practices,” says Updeep Singh, 57, CEO and president, STIL.

Meanwhile, the company has announced a greenfield project of 89,184 spindles at an estimated cost of Rs914 crore in Jammu & Kashmir. The project, funded through internal accruals and debt, will have the capacity to spin 75 tonnes per day of cotton mélange yarn and PC grey yarn, along with a dye house of 40 tonnes per day. Here the capex per spindle is higher due to the mélange yarn capacity, which requires almost double the back process, and a dyed yarn capacity of 40 tonnes, with zero liquid discharge.

-

The expansion project is also eligible for state government benefits – GST reimbursement of 300 per cent of the eligible plant and machinery amount for 10 years. Land has already been acquired for the project, while construction work will start soon, since the project will be implemented in Q4FY25. This additional capacity will take the company’s overall capacity to 375 tonnes per day, and will generate additional revenue of around Rs850 crore.

“This project is also strategic in nature since the company, with this expansion, will also enter grey yarn. Currently we are not present in the grey product segment. In order to complement the dyed/mélange product offering, the company needs to have a grey product in its product basket. In view of the increasing demand for cotton/polyester blends across multiple categories of end use there is market potential in grey blended yarns both in the domestic and export markets,” says Singh.

An industry veteran, Singh joined STIL in 2018 as deputy CEO and has been instrumental in leading several strategic initiatives. In April 2021, he was elevated as CEO and president of the company. With a prolific career spanning over 34 years, including global experience, Singh has a diverse range of expertise, include HR, marketing, sourcing and distribution. He started his career at Vardhaman Textiles in 1987 and served the company for almost 18 years.

Thereafter, he joined Welspun India Ltd as president (projects and commercial), handling different business roles across the Group. He then briefly served as the Chief Operating Officer at NSL Textiles Ltd and prior to joining STIL, served as managing director of global textile machine manufacturer, ITEMA, where he was responsible for the P&L of the Indian subcontinent operations of the weaving solutions business.

A responsible entity

At STIL, Singh has a mandate to carry out the initiatives the management started to make the company a robust organisation. For the last few years, amidst the Covid-related challenges, the company has prepared itself through its ‘Sustain. Empower. Grow’ positioning. It is now looking to build on its existing growth platforms as well as on a culture of product innovation and while doing so is positioning itself as a responsible and environment-friendly organisation.

“In fact, these three words encapsulate our response to an unpredictably volatile world where there are multiple challenges. Our performance in the last two years in the face of unprecedented business realities, has put a premium on seeking new ways to sustain ourselves and grow. There was a sharp rise in cotton price, crude oil, other commodities and interest rates. The outbreak of the Ukraine-Russia war affected global business sentiment, which in turn affected textile exports. There was a slowdown in the Chinese economy that moderated textile demand,” says Singh.

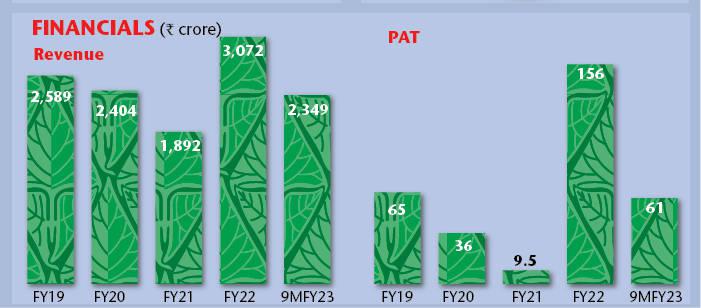

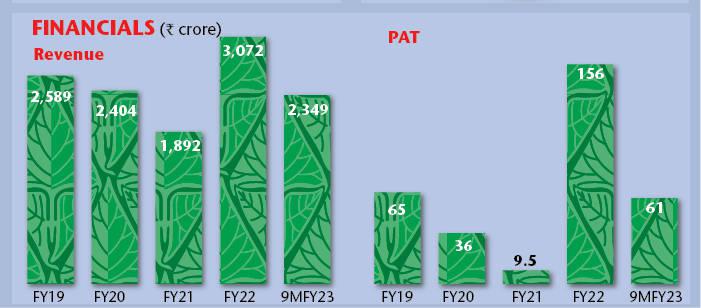

Despite these challenges, the company has shown a great deal of resilience. After 2 consecutive years of decline, revenue bounced back to Rs3,072 crore in FY22. In fact, it surpassed the pre-Covid level of Rs2,589 crore in FY19. In fact, the first two quarters of FY23 were also been quite impressive, even as the 3rd quarter of the year was down 19 per cent to Rs670 crore. The drop in sales was witnessed in both domestic and export markets. However, for the 9 months ended 31 December, 2022, consolidated sales were up by 6 per cent to Rs2,349 crore, led by growth in all markets.

-

The company has the largest product portfolio of spun-dyed, cotton blended and cotton melange dyed yarns

“The operating environment for our sector, like many others, continues to remain challenging. Weakening sentiments in the large economies on the back of inflationary pressures is causing harm for the textiles business and is creating a temporary imbalance in the value chain. Amidst these challenges, at Sutlej, our expanding product-portfolio, multi-market operations, fungible manufacturing and long-standing customers have ensured that we continue to post encouraging results,” says Rajib Mukhopadhyay, whole-time director & chief financial officer, STIL.

The macro headwinds of inflationary and cost pressures, high and uncompetitive prices and volatility in raw material prices and the distance from the downstream companies as well as recessionary concerns in key markets, all resulted in a contraction of almost about 11.5 per cent of India’s total textiles & apparel exports during the period April to December 2022. The share of textiles and apparel in India’s total merchandise exports declined to 7.93 per cent during April to December 2022, from 9.78 per cent in the previous year.

“The domestic market, although inherently stable, is also impacted by the current global scenario. At Sutlej, our long-term strategy of expanding our product offerings, strengthening our balance sheet and increasing our profitability continues to drive our operations. While our near-term performance may be impacted by global headwinds, we are confident of building a strong platform backed by our multi-market diversified product basket to cater to the opportunities in this sector,” says Nopany.

Over the years, the company has built a strong manufacturing set-up across its yarn and home textiles business. The company’s manufacturing units are equipped with a robust supply-chain system with superior knowledge and experience. The company’s spindleage across its three facilities grew from 1,56,000 in 2005 to 4,22,000 in 2022 and now with another greenfield project under implementation in J&K, the spindleage will cross 510,000 by FY25.

STIL is a one-stop textile solution for all kinds of spun dyed yarns manufactured from natural or manmade fibres across any blend and any shade in the count range of 6s-50s. It is present in two major yarn segments – cotton mélange and synthetic spun dyed yarn. Cotton mélange yarn is mostly marketed and sold to garment exporters for end use in knitting fabric.

The company is a major market player in the PV dyed yarn segment used for manufacturing suiting fabric. It also manufactures 100 per cent poly dyed yarn for sweaters and PA dyed yarn for dress material and saree manufacturing. The company has a competitive edge that enables it to produce multi-fibre (synthetic and natural) yarns across diverse applications, including synthetic and natural fibres, as well as grey, dyed and mixed varieties. This allows it to introduce unique products to the market.

The company is known for using sustainable fibres in its manufacturing process. These comprise recycled polyester (which facility has been set up recently), recycled cotton, organic/fair trade cotton, Seacell/smart cell, Cupro, Hemp, Linen, Lenzing, Modal, Tencel, bamboo fibre and bamboo charcoal fibre. Currently, the yarn business contributes to over 95 per cent of the overall revenue.

“There is a growing preference among consumers to buy apparel and textiles that are environment friendly. This includes a preference for clothes made from yarn using recycled fibre. There is a growing movement toward certifications that validate environment responsibility and sustainability. This is strengthening a trend for consumer-facing labels to reach out to vendors with sustainable practices. Sutlej is future-ready. The company invested in a 120 TPD green fibre manufacturing plant that consumes PET waste. This is not only helping in clearing the world of non-biodegradable plastic waste that would otherwise have been landfilled but is also transforming this waste into wealth and consumer utility,” says Singh.

-

STIL is a one-stop textile solution for all kinds of spun dyed yarns

Greener alternatives

Experts believe that the ‘green’ fibre product manufactured by the company is positioned such that it will transform the brand, apart from merely being a value addition designed to improve sales. Besides, the initiative addresses a growing consumer need to buy garments utilising recycled fibre. As prominent garment labels the world over replace synthetic fibres with ‘greener’ alternatives, a wider market has emerged for green fibre. The company’s manufacturing of green fibre has already resulted in almost 97 per cent capacity utilisation.

While STIL adds further value to its yarn business, it is also expanding its portfolio of home textiles. It has a home-textiles capacity of 8.4 million metres per annum, focusing on curtains and upholstery and has acquired ASM to enhance its reach in the US market. It also sells material through Amazon and Wayfair. The company also exports to the Middle East, USA and the EU, among others.

The home textiles business has a high gestation period and the customer order cycle is 3-6 months. For the domestic market, it launched a premium brand called Nesterra in FY21, which it markets at a wholesale level, thus addressing the cut-piece requirements of India’s retail sector. The company has strengthened its efforts to market more readymade products to major retail chains.

“STIL has differentiated itself with a focus on synthetic dyed yarn, mélange, and blends, which are seeing strong demand due to increasing cotton yarn prices. It has created a niche in specialised yarns, with a better margin profile, and has announced a capex of R900 crore, which will be operational from 4QFY25. The turnaround in home textile is likely to improve its profitability and return ratios,” says a PhillipCapital report.

With all these developments in place, STIL has positioned itself strongly in the market. On the one hand, it is enlarging its yarn business with more value additions; on the other it is moving up the value chain by aggressively expanding its home textile portfolio. The launch of the Nesterra brand is quite strategic for the company as it will allow it to come closer to the retail consumer and thus help build a brand that can represent the company’s overall business in the rapidly changing marketplace.

Recent uncertainties created by the pandemic and upheavals in the social-political environment, have forced the company to revisit its strategy in the market. However, backed by its recent initiatives, a new Sutlej is emerging, which appears to be more agile and resilient and which will, in the future, expand its market share even further.