-

Bhate: betting big on the Indian market which presents huge opportunities

The company serves these end users either directly or by partnering with EPC contractors like L&T, Megha Engineering & Infrastructure, Shapoorji Pallonji, Praj Industries and others. Xylem India has participated in a number of high-profile water projects in power, industrial, irrigation and water and wastewater treatment sectors in India. It has a project pipeline of over 25 projects.

“India is one of the focus markets for our global business,” affirms Nitin Bhate, managing director, Xylem India. “We are betting big on the Indian market which presents huge opportunities. Over the last few years, we have ramped up our capability in a big way and today we manufacture over 80 per cent of the products and solutions that we sell in India. Xylem is a leading water technology company committed to ‘solving water’ by creating innovative and smart technology solutions to the world’s water and critical infrastructure needs.”

The company provides end-to-end solutions for core foundational infrastructure, instrumentation and smart solutions. Xylem smart infrastructure focus segments include smart cities, smart real estate, smart irrigation, smart industrial infrastructure, smart mobility infrastructure (airports, ports, railways stations, inland water ways, sea ways and highways), smart mining and smart oil & gas.

Global leader

“Water is the essential foundation of life,” says Patrick Decker, president & CEO, Xylem Inc. “And it’s equally essential to development and growth. Xylem is a global leader in water technology, which makes solving the world’s toughest water challenges both our mission as well as our business. In India, those challenges include water scarcity, water affordability and the resilience of water infrastructure in the face of climate change.”

“We are privileged to be able to bring innovations that contribute to addressing water needs across India,” adds Decker. “We see great opportunity here, and continue to invest heavily in localising our capabilities for the Indian market – which includes building innovation, product management and engineering teams in India, as well as manufacturing locally. And, with those capabilities, we are expanding our work to address the most challenged communities across India with new water and sanitation solutions.”

Xylem India has built one of the world’s largest pump-testing facilities – of 7.5 MW and 80,000 m3/hour capacity – in Vadodara. The facility is capable of testing large, vertical turbine pumps, horizontal split case pumps, dry pit sewage pumps, booster systems, vertical multi-stage pumps and end-suction pumps for HVAC, plumbing and fire-fighting applications. All under one roof, the facility is spread over a 2,400 sq m area. It has an in-house electrical substation so that power can be utilised effectively for business operations.

The company’s Vadodara manufacturing unit is the only facility of Xylem’s global business, where it manufactures and carries out testing of large engineered custom pumps (capacity: up to 120,000 cu m/hour) in the water and wastewater, irrigation and power generation space. These large custom pumps (already supplied by Xylem India to some of the major irrigation projects including Kaleshwaram Lift Irrigation Scheme in Telangana) are made under Xylem’s flagship brand, Flygt.

“In India, we have built manufacturing facilities which are also part of our global supply chain,” claims Pralhad Kulkarni, director, operations, Xylem India. “We have localised a significant part of our manufacturing and will continue to ramp up this effort. Our Vadodara facility, known for making large custom pumps, caters to India and neighbouring countries by offering solutions for water and wastewater transport, treatment and testing, power, irrigation, commercial building services and municipal sectors.”

-

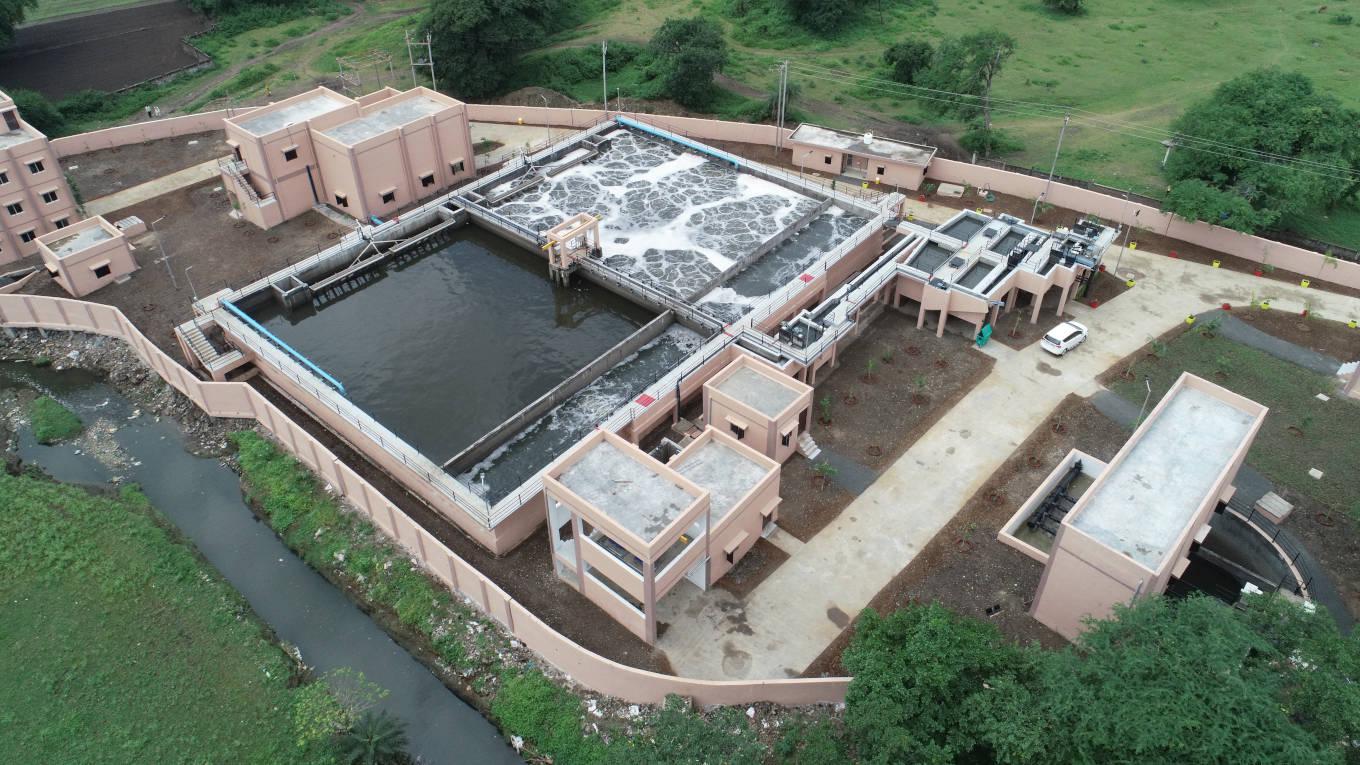

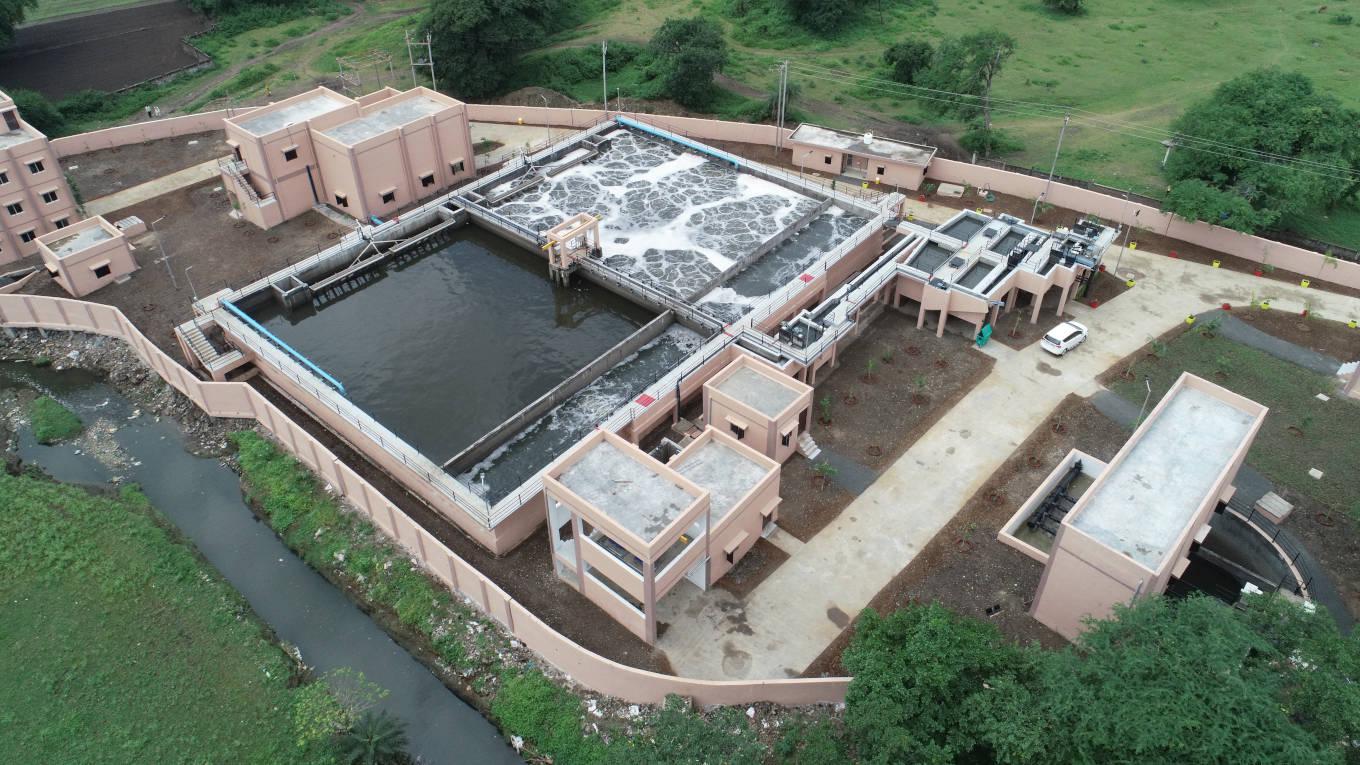

Sehore plant: resolving the wastewater challenge, thereby protecting the local environment and marine ecosystem

“We have built one-of-a-kind technology and customer experience centres in Vadodara and Bengaluru,” adds Sanjay Verma, senior director, India Technology Centre, Xylem India. “They outline the wide-ranging impact of adopting digital solutions, including the value realised internally within the utility (such as process optimisation, reduced capital expenditure, etc) and the value realised externally to the utility (like regulatory compliance, increased transparency and governance, etc). A broader perspective is then taken to bring forward the deeper shifts in the water sector, which are connected to this digital transformation across workforce, cities and homes.”

Apart from Flygt, which is a global leader in large custom pumps, Xylem has other brands under its belt, like Goulds (centrifugal and turbine pumps, controllers and drives); Godwin (a global leader in fully automated self-priming pumps); Bell & Gosset (a leading manufacturer of pumps, valves, heat exchanges and accessories for plumping, waste water and HVAC – including steam and heat transfer applications); Leopold (which is into rapid gravity media filtration and clarification solutions); Lowara (a leading pump and drives maker, offering complete solutions for water supply, wastewater, HVAC and fire protection in agriculture, building services, commercial and industrial applications); WTW (offers analysis of products for the measurement of pH, dissolved oxygen, conductivity and total dissolved solids and specific ions); and Sensus, which helps public service providers to reach farther by responding to evolving business needs with innovations in sensing (smart water meters) and communications technologies, data analytics and services.

End-to-end solutions

Xylem has built up this strong portfolio of globally-renowned brands across multiple verticals of its business by acquiring many of them over the past decades. Sensus was acquired in 2016 for a cash transaction of around $1.7 billion. A US brand, Sensus, founded in 1870, was owned by investment funds affiliated with The Jordan Co and GS Capital Partners 2000. Xylem acquired the brand as part of its global acquisition strategy to create a full end-to-end solution for the global water market.

The US-based company started its India metering operations in 2014 and has worked closely with various utility bodies and organisations offering its expertise in smart metering, data analytics, smart water networks, automatic meter reading and advanced metering infrastructure. Sensus brings its experience and learning from its successful execution of one of the world's largest smart water projects to date – The Thames Water Smart Metering Program. Thames Water will install over three million smart water meters to address the shortfall in water supply that is predicted in London, UK, by 2040.

It has also been selected as Larsen & Toubro's technology partner to successfully implement Pune Municipal Corporation's (PMC) innovative 24x7 water distribution project which aims to ensure continuous water supply and increased operational efficiency. PMC, as the first city in India to implement a programme aligned to the country's Smart City Mission, has invested in over 300,000 Sensus iPERL smart water meters to measure and manage water supply across its network.

“We are proud to be the first Indian city to deploy cutting-edge smart water meters,” remarks VG Kulkarni, Chief Engineer, PMC, commenting on the deployment. “This is just the first step on our journey towards making Pune a more sustainable and self-sufficient city committed to conserving water. We are confident that Sensus is the right partner to ensure we achieve these goals.”

-

Decker: solving the world’s toughest water challenges both our mission as well as our business

“Smart water metering is the key to addressing India's non-revenue water challenge and, hence, pivots huge water and revenue savings,” comments Amit Vaidya, director, India, metrology business, Sensus. “Sensus' advanced smart metering solutions, like iPERL electromagnetic smart water meter, with inbuilt bi-directional communication capability provides unrivalled, sustained measurement accuracy which enables water utilities with reliable consumption information to identify and address apparent losses.”

“Water loss programmes and investments in smart water technologies, particularly advanced metering systems, will help utilities and citizens conserve and better utilise water in India,” surmises Vaidya. “The government of India has been vocal and encouraging about the digital water economy movement and has already deployed smart water infrastructure in key cities. Xylem is in talks with state governments and municipalities to help them add smartness into their water distribution network.”

“Our brands serve several industries – agricultural, infrastructure, construction, environmental, food & beverages, government agencies, industrial, public utilities, residential and commercial building services,” explains Bhate. “These strong product brands will continue to drive our business forward in moving, testing, analysing and treating water, and are the essential building blocks of the Xylem brand. With decades of leadership in their categories, these brands are at the core of who we are, and each is part of the new, revitalised future we’re creating together at Xylem.”

In the short span of time spent on its Indian operations, Xylem India has created a strong presence for itself in the Indian market. Apart from selling its products across multiple sectors and businesses, the company, along with its partners (primarily EPC players like L&T, Megha Engineering and Infrastructure and others) has been ramping up its project portfolio, even as it executes about 25 projects.

In the Kaleshwaram Lift Irrigation Scheme (KLIS), Xylem India works with Megha Engineering & Infrastructure, the contractor of the project and has supplied 14 large Flygt A-C custom-made metallic volt pumps of 40 MW, each capable of lifting 75,000 litres of water per second to a height of 35 metres for Sundilla pump house. KLIS, one of the world’s largest multistage lift irrigation projects built over Godavari river in Kaleshwaram, Telangana, aims to harness the flood waters of the Godavari to make Telangana drought-resistant. It is proposed that these pumps draw water from the foreshore of Sundilla Barrage and pump it into the Sripada Yellampalli Project.

KLIS is divided into seven links and 28 packages to build 20 reservoirs in 13 districts, which can hold 141 TMC of water. These reservoirs are interconnected through tunnels running to about 330 km, including the longest, a 21 km tunnel connecting Yellampalli and Medaram reservoirs. The canals will be 1,832 km-long, taking water as far as 500 km from the source. And it will be pumped up to 618 metres from mean sea level — the highest point of KLIS — into the Kondapochamma reservoir in Gajwel. The KLIS project is designed to provide water for irrigation and drinking purposes to about 45 lakh acres in 20 of the 31 districts in Telangana, as well as Hyderabad and Secunderabad.

-

Xylem customer experience centre

Sewage treatment

In another mega project, the Sardar Sarovar Project, one of the largest water resources projects in the country, covering four major states – Maharashtra, Madhya Pradesh, Gujarat and Rajasthan – Xylem India, working again with contractor Megha Engineering & Infrastructure, has supplied and commissioned 27 Flygt AC Vertical Turbine pumps (pumping capacity: 72,000 cubic metres per hour) to pumping stations for the Saurashtra Branch Canal, a part of the Narmada Project Canal system. These pumping stations provide water to 24 million people in that region. The Saurashtra branch is the largest of the 38 branches of the Sardar Sarovar Canal (Narmada Main Canal), and is around 104 km long. It discharges some 424 cubic metres per second.

Recently, the city of Sehore in Madhya Pradesh had experienced unhealthy and unhygienic conditions due to poor sewerage management. The untreated sewage was discharged into the River Siwan, resulting in its contamination. Here Xylem India helped resolve the wastewater challenge, thereby protecting the local environment and marine ecosystem. The municipal corporation of Sehore appointed Ankita Construction to build and manage the 12-million-litres-per-day sewage treatment plant in the city. It was the first sewage treatment plant that was constructed under the government of India’s AMRUT programme, which aims to establish infrastructure ensuring adequate robust sewage networks and water supply for urban transformation by implementing urban revival.

Xylem India partnered with Ankita Construction to supply advanced wastewater treatment technology based on the ICEAS process for this plant. Xylem’s ICEAS (advanced SBR technology) provided a significant advantage in terms of low footprint, reliable and robust controls, low capital, operation and maintenance costs, which ensured the wastewater discharge quality standards of the Madhya Pradesh Pollution Control Board were adhered to.

“The sewage treatment plant was commissioned in 2018 and has been successfully running since then,” says Jignesh N Pandya, director, execution, Xylem India. “It has benefited over 14,000 households of the area, enriching their quality of life. There is also improvement in the water quality of the River Siwan, as the BOD of treated water discharged is less than 10 ppm. Our solution helped solve the wastewater challenge, thereby protecting the local environment and marine ecosystem.”

The presence of industrial and commercial activities had a strong impact on the ecological quality of the city of Jamnagar in Gujarat. In 2013, Jamnagar Municipal Corporation (JMC), Marine National Park & Sanctuary (MNP&S) and Gujarat Pollution Control Board (GPCB) worked in co-ordination to set up an efficient sewerage treatment plant in Jamnagar and minimise the impact of untreated sewage disposal on the coastal and marine environment. JMC was given responsibility to implement, operate and maintain the sewerage project in the city.

JMC invited international competitive bidding to design, build, operate and maintain a 70 MLD capacity sewage treatment plant at Jamnagar on DBOT basis, including 15 years post-commissioning operations & maintenance with appropriate technology. The project was funded by the World Bank as a part of the Inter Coastal Zone Management (ICZM) project, monitored by the Gujarat Ecology Commission and the government of Gujarat.

EPC contractor Essar Projects (EPL) and Thermax JV secured this project from JMC and decided on Xylem’s ICEAS for the STP, as it offered a cost advantage (reduced capital cost due to 30 per cent less basin volume) and reduced operating, installation and maintenance costs, due to its high energy-efficiency diffused aeration system and reliable instruments and robust control system.

-

Kaleshwaram Lift Irrigation Scheme: harnessing the flood waters of the Godavari to make Telangana drought-resistant

The JMC STP project started in July 2013 and was commissioned successfully in July 2016. In the installed STP, sewage water is collected from the city and transferred to the treatment plant through extensive pipelines. Solid sewage sludge that gets filtered out is treated using anaerobic technology for vermin-composting to create bio-fertilisers.

Last year, during the pandemic, when the entire country was facing a strict lockdown, the biggest challenge was ensuring business continuity for most manufacturing industries. One of the largest pulp and paper units in Telangana faced severe pressure. The unit is known for using advanced, green and eco-friendly technology for paper manufacturing. It uses Xylem’s WEDECO branded ozone system for bleaching applications.

Despite all the challenges, Xylem provided personnel and services and ensured uninterrupted supply of ozone for their process. The ozone producing technology provided by Xylem is robust and, with the support of its operation, this pulp & paper unit in Telangana was able to use ozone when required.

“We work closely with our customers and partners and help them resolve their issues in a holistic manner with our products and solutions,” explains Bhate. “We boast of having one of the largest ranges of solutions across the entire water cycle and solving water-related issues. All our brands, known globally for their proficiency and problem resolving abilities, work in tandem and help build a one stop platform for our valued customers.”

Project-focussed model

Bhate was elevated to the helm of the Indian operations in August 2020, prior to which he was the senior marketing director & treatment business leader, Xylem India. A BTech in Mechanical Engineering from IIT Mumbai, with a PhD from Brown University and an Executive MBA from IIM Bangalore, he had previously held technology & commercial leadership roles at General Electric, both in the US and India.

In the last few years, Xylem India, in particular, has adopted a strategy, where it looks to pursue a project-based approach rather than limiting itself to just the supplying of products and services. Over 70 per cent of its business today comes from projects and that has not only helped it expand its business at a faster pace, but has also given it an edge over its competitors. “Our project-focussed model has paid rich dividends,” adds Pandya. “And, going forward, we will continue to pursue this strategy in a more aggressive manner and ramp up our presence in India, where opportunities are immense. As a country, India has its own sets of issues and we are fully committed to resolve then with our customised solutions.”

“Xylem offers a portfolio of products and systems designed to effectively meet the demands and challenges of transporting, treating, testing water and wastewater,” reveals Rajul Mehrotra, director, strategy, marketing, business development & product management, Xylem India. “From pumps to smarter aeration to advanced filtration to chemical-free disinfection to monitoring & control solutions, Xylem's experts evaluate the varying needs of customers and help them find the right solutions for their applications. Through the brands that have been trusted for decades, Xylem offers hundreds of solutions, backed by a comprehensive, integrated portfolio of services designed to ensure that water and wastewater equipment keeps running at its best.”

Xylem India has created a distinct edge for itself in the market, competing with players like Flowmore, Jyoti, Kirloskar, Andritz, and Wilo in large pumps; Kirloskar, Grundfos, Wilo and KSB in building services pumps and C-Tech, Napier Reid, P-Tech, Calgon Carbon, Trojan UV, Ozonia, Toshiba in the treatment and filtration category. While most of its competitors have a presence in certain segments, Xylem enjoys a presence across the full water cycle.

-

Technology centre at Bengaluru: adopting digital technology

“We listen, learn and adapt to local environments, working in true partnership with our customers,” contends Bhate. “With deep application expertise in the water industry, we focus on producing highly efficient water technologies that use less energy, reduce lifecycle costs, and provide environmental benefits to users and the communities in which they operate.”

Experts are of the view that India presents huge opportunities across the entire water cycle space. India being an agro economy (agriculture uses over 80 per cent of fresh water), there is a call for better management of water resources. The scientific management of water is increasingly recognised as being vital to India’s growth and ecosystem sustainability. India accounts for about 17 per cent of the world’s population but has only 4 per cent of the world’s fresh water resources. With 1,544 m3 per capita water availability, India is already a water-stressed country according to international norms.

While the private sector is working, building up its capability, the government of India has been proactive about water management and has created the Ministry of Jal Shakti to consolidate interrelated functions pertaining to water management. The newly formed Jal Shakti Ministry strives to bridge over the water challenge by launching the Jal Shakti Abhiyan – a campaign for water conservation and water security in 1,592 water stressed blocks in 256 districts, to ensure five important water conservation interventions.

The government advocates the adoption of best practices in the water sector across India and recognises that data-based decision making is going to be key to effective water management. NITI Aayog has developed the Composite Water Management Index (CWMI) to enable effective water management in the Indian states.

With all these developments in place, Xylem India is well placed to explore the opportunities across the full cycle of water. The company, backed by a strong portfolio of global brands across various segments of the business, is a dominant player in the water technology space. With water becoming a scarce commodity, conserving and replenishment will be paramount and that is where water technology aimed at resolving issues is quite crucial.

Xylem, with a rich heritage (ITT Corporation) and an array of products and solutions, commands a formidable share in the market. Moreover, being present across the full cycle of water – from extraction, treatment, transportation and recycling – provides it a distinct edge over the competition as most of its competitors cater to a particular segment of the value chain.